Hillsdale fabricated and erected 13,500 tons of structural steel for the world’s first LEED certified automotive assembly plant – General Motors-Lansing Delta Township. This 1.7 million-square-foot, is a campus-style automotive assembly facility comprised of a body shop, general assembly, administration building, and visitors arrival center interconnected by 101,000 square-feet of elevated conveyor/utility trestles. Raw coiled […]

Hillsdale Fabricators was the prime steel contractor responsible for the fabrication and erection of more than 15,500 tons of structural steel for this retractable roof stadium that is home to the NFL’s Indianapolis Colts. The stadium’s retractable roof was the first to part lengthwise and boasts an operable glass window wall, allowing for a spectacular […]

When Indianapolis unveiled its new $1.1B Midfield Terminal and Concourses, Hillsdale Fabricators was looked to by the project’s prime steel contractor, Cives Steel Company, to fabricate the serpentine structural roof trusses and tapered-pipe columns. The roof trusses are 10 feet deep with a wide-flange top chord 6G welded to diagonal and vertical pipe that is […]

The Huey P. Long Bridge project in Jefferson Parish, Louisiana included the expansion of US 90 to three lanes in each direction, while keeping the pre-existing railway that also shares the bridge. Hillsdale Fabricators supplied approximately 1,800 tons of lifting structures and falsework which were fabricated, preassembled and then shipped by barge to Louisiana from […]

Hillsdale fabricated, preassembled, and shipped the 156-foot-long tied-arch bridge to replace the 103-year-old Halsted Street bascule bridge over the Chicago River North Branch Canal. The bridge features a 156-foot-long, 180-foot-wide steel tied arch main span flanked by two 36-foot precast concrete arch approach spans. The new bridge deck is 22 feet wider than the old […]

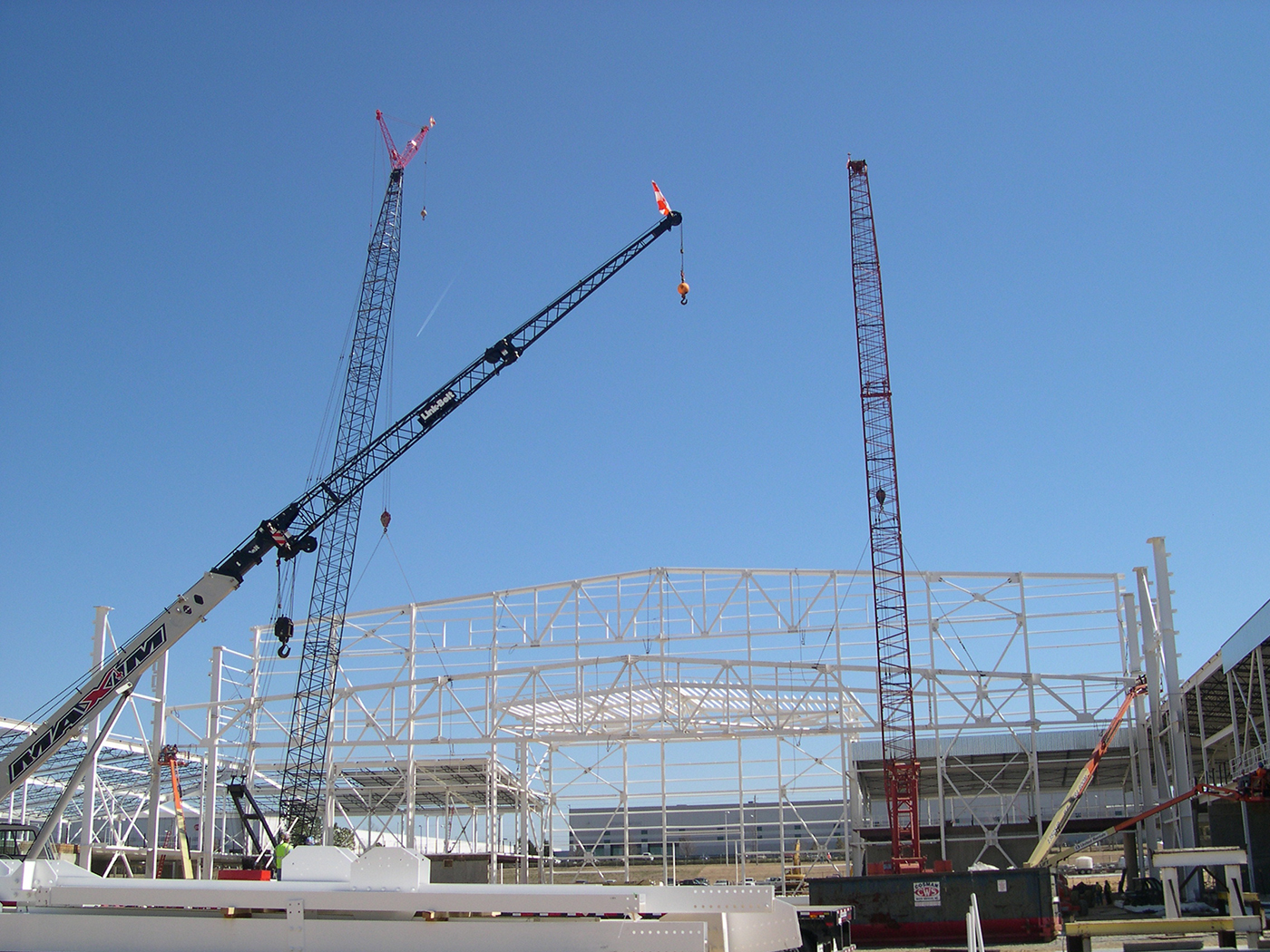

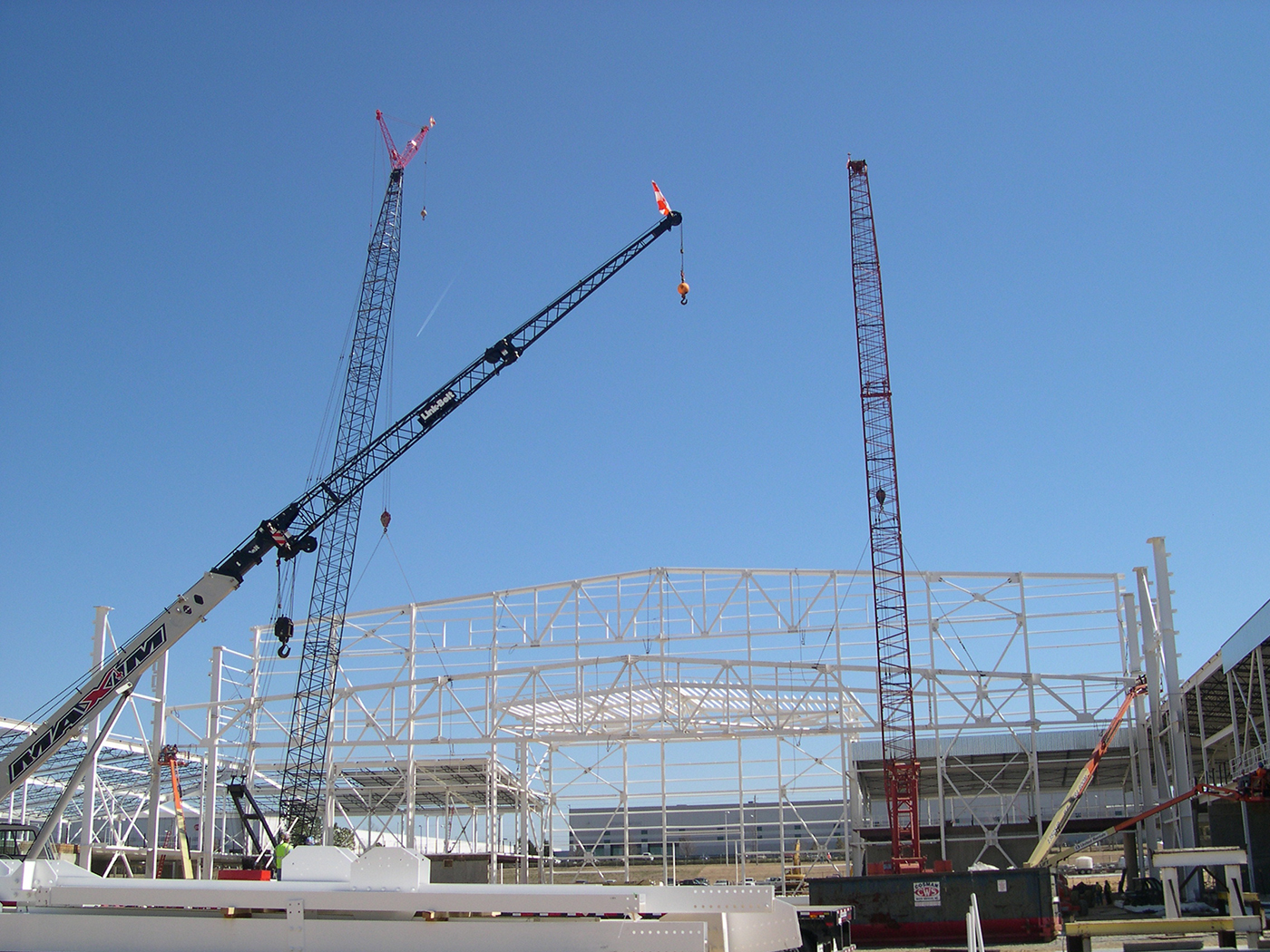

Chrysler challenged the Alberici/Hillsdale team to apply the “Low-Cost Building Strategy” to this project. The application would dramatically reduce the comparable cost of assembly plant facilities and subsequently reduce the cost of automobile manufacturing. Traditionally, the cost to build a manufacturing facility is $85/SF. The team worked in tandem with the architect and Chrysler to […]

The C-5 Hangar Facility for the 164th Airlift Wing of the Tennessee Air National Guard accommodates eight C-5 Galaxy cargo planes that support military and humanitarian operations throughout the world. The project featured construction of a new maintenance hangar, corrosion control hangar, fuel cell hangar, and associated support facilities totaling approximately 330,000 square feet. In […]

Hillsdale Fabricators performed structural steel fabrication and erection for the 614,000-square foot BJC North Campus Integration Project, which created both the Center for Advanced Medicine and Alvin J. Siteman Cancer Center. Stringent seismic requirements of the building code for called for the support of a sophisticated structural steel system. Hillsdale responded to the challenge with […]

The largest electric utility in Missouri, Ameren Corporation, chose Hillsdale Fabricators as its prime steel contractor in support of its Environmental Upgrade program. The program covered three facilities, Portage des Sioux, Duck Creek and Coffeen Power Stations. Hillsdale provided structural steel and ductwork to all three stations for their respective environmental programs including SCR’s, scrubbers, […]